Highly filled graphite/polymer composites

One research topic in the department is the development of highly filled graphite/polymer-based materials with up to 90 wt% graphite. These materials can be used as bipolar plates in fuel cells or redox flow batteries. The prerequisite for this is a high electrical conductivity with simultaneously high thermal conductivity. This makes it possible to substitute metallic bipolar plates, whose high weight, high material price and low chemical resistance are disadvantages. In addition, the developed graphite/polymer recipes can also be used as plates in planar heat exchangers, for which a high thermal conductivity is desired. For both applications, the high corrosion resistance of graphite/polymer materials to e.g. acids (battery) or salt water and electrolytes (heat exchanger) is of great importance.

Bipolar plates

One challenge is to reduce the brittleness of the material, which contains up to 90 wt% graphite, without reducing the electrical and thermal conductivity. The IPF's innovative idea was to incorporate an elastomeric component and apply the concept of polymer blends. For polypropylene with 80 wt% graphite, mechanical tests showed that the addition of 6 wt% elastomer led to an increase in impact strength to 220% and flexural elongation to 460%, as well as a reduction in flexural strength to 40% compared to a formulation without elastomer. At the same time, the processability was significantly improved.

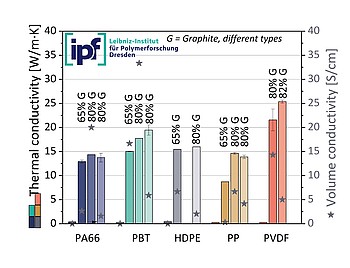

Formulations of different polymers (polyamide (PA), polybutylene terephthalate (PBT), polyethylene (PE), polypropylene (PP), polyvinylidene fluoride (PVDF)) and graphites were developed and investigated. Thermal conductivities up to 26 W/(m·K) and electrical conductivities up to 34 S/cm were achieved. Composites based on PVDF proved to be the most promising material combination for bipolar plates. In a hydrogen-powered fuel cell built by the company Eisenhuth GmbH & Co.KG, it was shown that the current density is doubled compared to conventional PP/graphite plates.

Heat exchanger plates

For the application in the heat exchanger, the heat transfer coefficients of the materials were determined in addition to the thermal conductivities. For PP-, PE- and PVDF-based composite materials, a fivefold increase in the heat transfer coefficient was achieved by adding graphite as compared to the pure polymer. This means that five times the amount of heat can be transferred with the same surface area, or the surface area of the heat exchanger can be reduced to 20% for the same amount of heat transfer. In addition, the addition of graphite to PVDF-based heat exchanger plates leads to a significant cost reduction compared to pure PVDF plates. Possible areas of application are the cooling of redox flow batteries and the temperature control of salt water pools.

Contact persons

Dr. Beate Krause

Dr. Petra Pötschke

Flyer