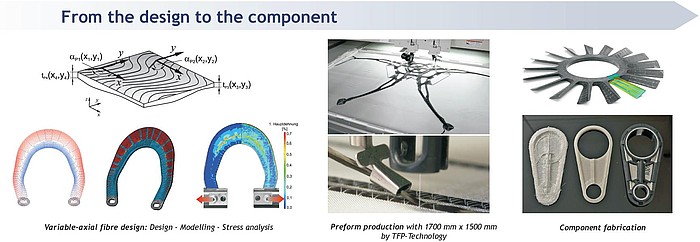

To be able to realize fibre arrangements that meet the calculated requirements concerning direction and accumulation of fibres, we developed the Tailored Fibre Placement (TFP)-Technology, numerical design methods and process software for computable complex fiber reinforced parts.

The reinforcement structure is produced by the lay up of a single roving. This roving is fixed by stitching to the base material. The base material can be a 2D-textile such as a woven fabric or for thermoplastic composites a matrix-compatible foil material. During the process, the stitching unit is stationary and the base material is moved using numerical control. more