Multicomponent Inkjet Printing of Cell-Instructive Hydrogels

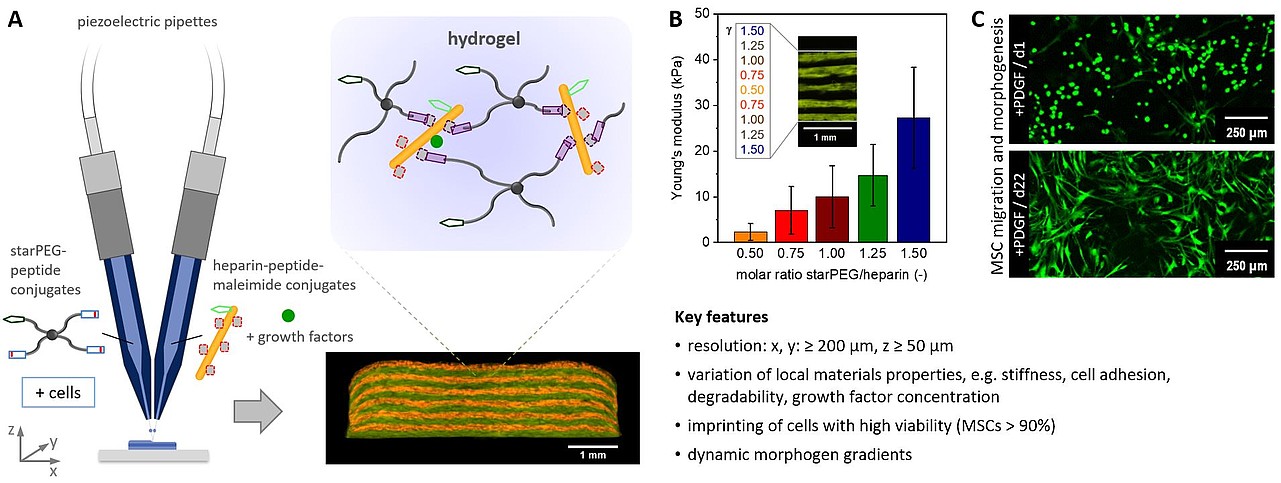

Biomaterials that precisely mimic structural and biomolecular cues of extracellular matrices (ECM) are crucial to control cell fate decisions and thus for progress in tissue engineering. We developed a multi-component inkjet bioprinting method that allows for spatially varying composition and network properties in cell-instructive glycosaminoglycan (GAG)-based biohybrid and pure poly(ethylene glycol) hydrogels in the order of ~50 µm. The gel formation relies on the covalent crosslinking of polymeric precursors through a Michael type addition that occurs during the fusion of bio-ink droplets prior to and upon contact with the target. Applying the method, hydrogel scaffolds can be tailored spatially in structure, composition, mechanical properties, and biomolecular functionalization. Furthermore, cells can be printed with a high viability into these scaffolds. The various options for the formation of biomolecularly and mechanically instructive materials provide a versatile platform for controlling cell fate decisions by the presentation of spatially varying physical and biochemical cues and to mimic tissue boundaries in advanced in vitro and in vivo studies.

Inkjet printing of reactive precursor solutions to fabricate multiphasic materials for tissue engineering. (A) Simultaneous dispensing of precursor solutions onto pre-functionalized cover slips using piezoelectric pipettes and cross-section of a hydrogel scaffold consisting of alternatingly printed starPEG-heparin (labeled with Atto-532, green) and starPEG (labeled with Atto-610, red) hydrogel layers. (B) Young’s moduli measured at cross-sections of a starPEG-heparin scaffold with zonally graded molar ratios of starPEG to heparin. (C) Morphogenesis of hMSCs by PDGF-BB gradients in 3D printed, zonally graded starPEG-heparin hydrogels. Adapted from Ref. [1].

References:

[1] Zimmermann et al. Biofabrication 2019, 11, 045008, doi: https://doi.org/10.1088/1758-5090/ab2aa1